Noteworthy Technology Feature of Egg Tray Production Line

- By Little Dianne

- •

- 06 Jul, 2018

- •

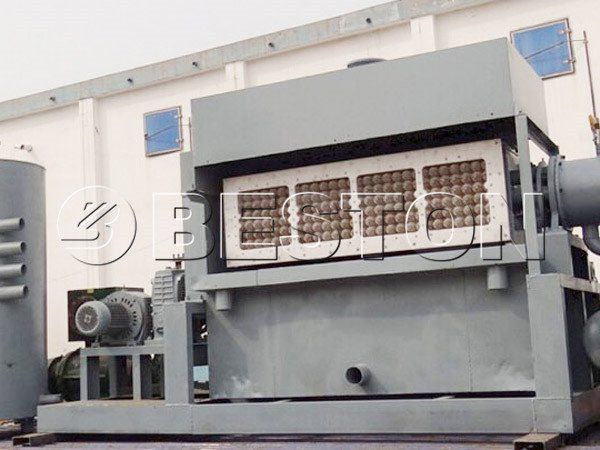

With regards to efficient and environment-friendly manufacture of egg containers, an egg tray production line is the most preferred choice. It’s designed with productivity and seamless functioning in mind much so that it practically doesn't have equal in that way. If you’ve been meaning to discover just how economical and capable this egg tray production line for sale

is, find time and energy to learn about its myriad features below.

Technology Feature of Egg Tray Production Line

1. Permits the recycling of waste paper materials, minus the pollution.

Egg tray production lines hit two birds with one stone as they not merely produce high-quality egg trays, but additionally will address persistent waste issues, particularly that regarding paper. It works with just about something that comprises of paper for example old newspapers, recycled papers, cartons, etc. Another distinct good thing about employing an egg tray production line is they also don’t at all give rise to pollution. Click here to know more: http://eggtraymachines.net/.

2. Could be semi-automatic or fully-automatic.

This kind of technology of egg tray production line ensures their productivity. Each possesses his own advantage, but are proven to save on labor costs and operates as a veritable way to save time at the same time. The reason being with such technology, you won't be required to depend on manpower to perform a number of the integral processes such as the cleaning of molds or ensuring there are no undesirable materials (like adhesives) are added to the mix. Automation also guarantees there is certainly retention of quality in all the egg trays produced.

3. Uncomplicated operation and maintenance.

Lots of other machines available which has a similar purpose can’t the same. This selection of egg tray production line belongs to why them the more attractive choice for companies. It’s never nearly impossible to find a hang of their functionalities, as is also just about made to perform step-by-step processes that entail pulping, forming, and drying.

Usually the one in charge of pulping can often be known as a hydrapulper. This tools accounts for beating the paper into a pulp, with a specific programmed consistency. Afterwards, the forming process starts, which is usually completed with a molder, that's usually consisting of a certain quantity of egg tray molds. In a few machines, a water spraying strategy is usually used to maintain the molds clean. Finally, the drying part begins, which can be commonly done by using a dryer conveyor that the finished molds are transferred.

After the three processes are completed, the cycle just starts anew. This kind of feature of egg tray production lines actually highlight its efficiency as supported by the fact that it doesn’t take more than ten seconds to accomplish the full cycle for most automated machines. The price of egg tray machine is competitive.

4. A variety of molds for a number of purposes.

Other egg tray production lines also incorporate distinct types of molds, that are not restricted to the production of egg trays. It's also possible to form other shapes using them that make them good containers for vegetables, cans, and fruits, for example, at the same time. Its versatility lies in the reality that you can pick to buy types of molds and employ them to produce the ones that you need to fulfill a unique demand or purpose.

Technology Feature of Egg Tray Production Line

1. Permits the recycling of waste paper materials, minus the pollution.

Egg tray production lines hit two birds with one stone as they not merely produce high-quality egg trays, but additionally will address persistent waste issues, particularly that regarding paper. It works with just about something that comprises of paper for example old newspapers, recycled papers, cartons, etc. Another distinct good thing about employing an egg tray production line is they also don’t at all give rise to pollution. Click here to know more: http://eggtraymachines.net/.

2. Could be semi-automatic or fully-automatic.

This kind of technology of egg tray production line ensures their productivity. Each possesses his own advantage, but are proven to save on labor costs and operates as a veritable way to save time at the same time. The reason being with such technology, you won't be required to depend on manpower to perform a number of the integral processes such as the cleaning of molds or ensuring there are no undesirable materials (like adhesives) are added to the mix. Automation also guarantees there is certainly retention of quality in all the egg trays produced.

3. Uncomplicated operation and maintenance.

Lots of other machines available which has a similar purpose can’t the same. This selection of egg tray production line belongs to why them the more attractive choice for companies. It’s never nearly impossible to find a hang of their functionalities, as is also just about made to perform step-by-step processes that entail pulping, forming, and drying.

Usually the one in charge of pulping can often be known as a hydrapulper. This tools accounts for beating the paper into a pulp, with a specific programmed consistency. Afterwards, the forming process starts, which is usually completed with a molder, that's usually consisting of a certain quantity of egg tray molds. In a few machines, a water spraying strategy is usually used to maintain the molds clean. Finally, the drying part begins, which can be commonly done by using a dryer conveyor that the finished molds are transferred.

After the three processes are completed, the cycle just starts anew. This kind of feature of egg tray production lines actually highlight its efficiency as supported by the fact that it doesn’t take more than ten seconds to accomplish the full cycle for most automated machines. The price of egg tray machine is competitive.

4. A variety of molds for a number of purposes.

Other egg tray production lines also incorporate distinct types of molds, that are not restricted to the production of egg trays. It's also possible to form other shapes using them that make them good containers for vegetables, cans, and fruits, for example, at the same time. Its versatility lies in the reality that you can pick to buy types of molds and employ them to produce the ones that you need to fulfill a unique demand or purpose.